PRODUCTSFor Better Construction & Safer Future

Epoxy Coated Rebar

Epoxy coated rebars are produced by applying quality standards according to KS D3629 and ASTM A 775-A 775M.

It is a civil construction material that guarantees the safety from high altitude sea or underwater conditions. and economic feasibility of the structure by enhancing the durability of all reinforced concrete structures exposed to acid rain or base, such as marine, underwater, highland, etc.

Advantage and characteristics of Epoxy-coated Rebar

-

Recently, rebar corrosion in reinforced concrete has become an issue.

This is due to the widespread corrosion of the actual structure, which has led to a sharp increase in repair costs.

Corrosion of rebars was first issued in marine and chemical resistant structures, and various structures exposed to base, such as bridge tops, parking spaces, reinforcement of cut slopes, and construction of sewage treatment plants, were studied.

Epoxy coated reinforcement is an eco-friendly civil construction material with excellent anti-corrosion ability and excellent corrosion resistance by directly imparting anti-corrosion performance to the rebar itself through the manufacturing process of coating.

Advantages of epoxy coated rebar

-

Epoxy coated rebars provide extra service life and prevents the corrosion.

Epoxy Coated Rebar

- Increases the building performance

- Provides extra service life for building

- Provides 40-50 times extra corrosion resistance.

- Can be used in any type of environment which is under corrosion risk

- Epoxy coated rebars provide extra service life and prevents the corrosion.

- Epoxy coating provides 40-50 times extra protection against corrosion compares to standard rebar.

- Epoxy coated rebar can be used any concrete block subject to extreme corrosion environment. Such as ice, solvents and marine conditions.

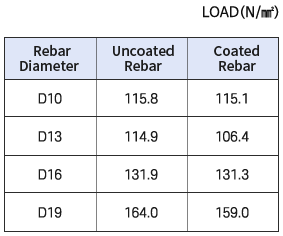

The superior coating consistency allows for bond stress equivalent to that of a regular uncoated rebar